Cleaning facilities

FTT's cleaning products are tailored for customers in terms of technological features and user-friendliness. All processes and the entire machine technology have been tested in continuous operation and optimized over the years through own application by our affiliated company FRG Filter Recycling GmbH.

As a competent partner, we are able to offer you not only high-quality machines, but also sophisticated processes. FTT specializes in the individual components of solvent cleaners, vacuum pyrolysis cleaning facilities, various post-cleaning and testing systems, as well as turnkey cleaning concepts with complete engineering.

Solvent cleaning

Sensitive machine parts such as filter elements and spinning nozzles are cleaned very carefully here. A standard version is available for use of triethylene glycol (TEG, C6H14O4) as a solvent for complete removal of PET, PBT, PA, PC, PU and other polymers of machine parts. Available on request are special versions for other solvents, as well as fully automatic process-control systems based on programmable microprocessors or PLC.

The concept includes all necessary safety devices to protect personnel, equipment and the environment. Various sizes are available for heating and circulation of solvents. Solvent recovery is available as an optional accessory.

Cleaning in a multi-stage process.

Vacuum-pyrolysis cleaning facilities

Polymers are removed from machine parts by the action of thermal energy (ΔH) in a vacuum. Standard versions here are designed to completely remove all typical fibre and film polymers such as PET, PBT, PA, PC, PU, PE, PP and others from machine parts. Special designs for removal of other specific polymers are available on request. Moderate process conditions spare machine parts while optimizing the cleaning effect. Only electricity and water are required.

Cleaning is performed with the help of programmable microprocessor control or PLC to minimize staff deployment. All safety devices necessary to protect persons as well as facility and machine components to be cleaned are available. Through appropriate post-treatment of exhaust gases, environmental pollution is limited within the framework of applicable regulations. Facilities of various sizes are available for horizontal and vertical assembly.

Chemical post-cleaning baths

Post-cleaning baths achieve effective removal of all kinds of foreign substances, especially inorganic impurities of filters, spin packs, melting pumps and other machine parts through cleaning in tempered, chemically active liquids. Available are standard versions for use of alkaline (OH-) and acidic (H+) chemicals with additives, as well as special versions for removal of special impurities or use of special chemicals. Fully automatic processes with programmable microprocessor control ensure minimal staff deployment.

Facilities of various sizes with electric, steam or thermal-oil heating are available.

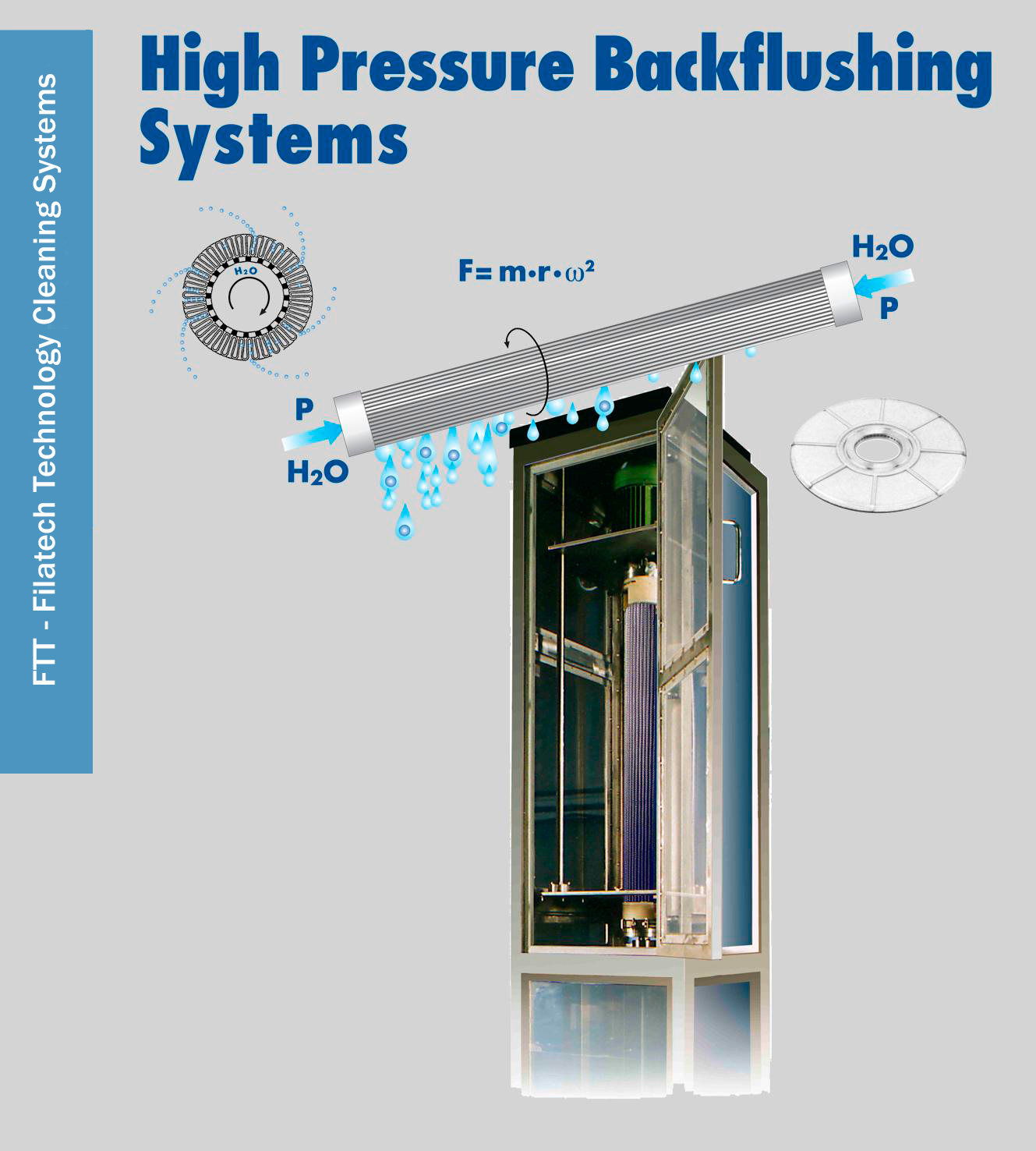

High-pressure post-cleaning (Autojet)

These protected systems are meant for optimal final cleaning of cylindrical cartridge filters. In the standard version, rinsing by means of a high-pressure water jet and a simultaneously applied centrifugal force (F = m ∙ r ∙ ω 2) remove foreign objects from the pores of the filter media. Other final cleaning systems are not able to achieve such cleaning results.

A fully automatic process with programmable microprocessor control minimizes staff deployment. Systems for different sizes and cartridge filters are available.

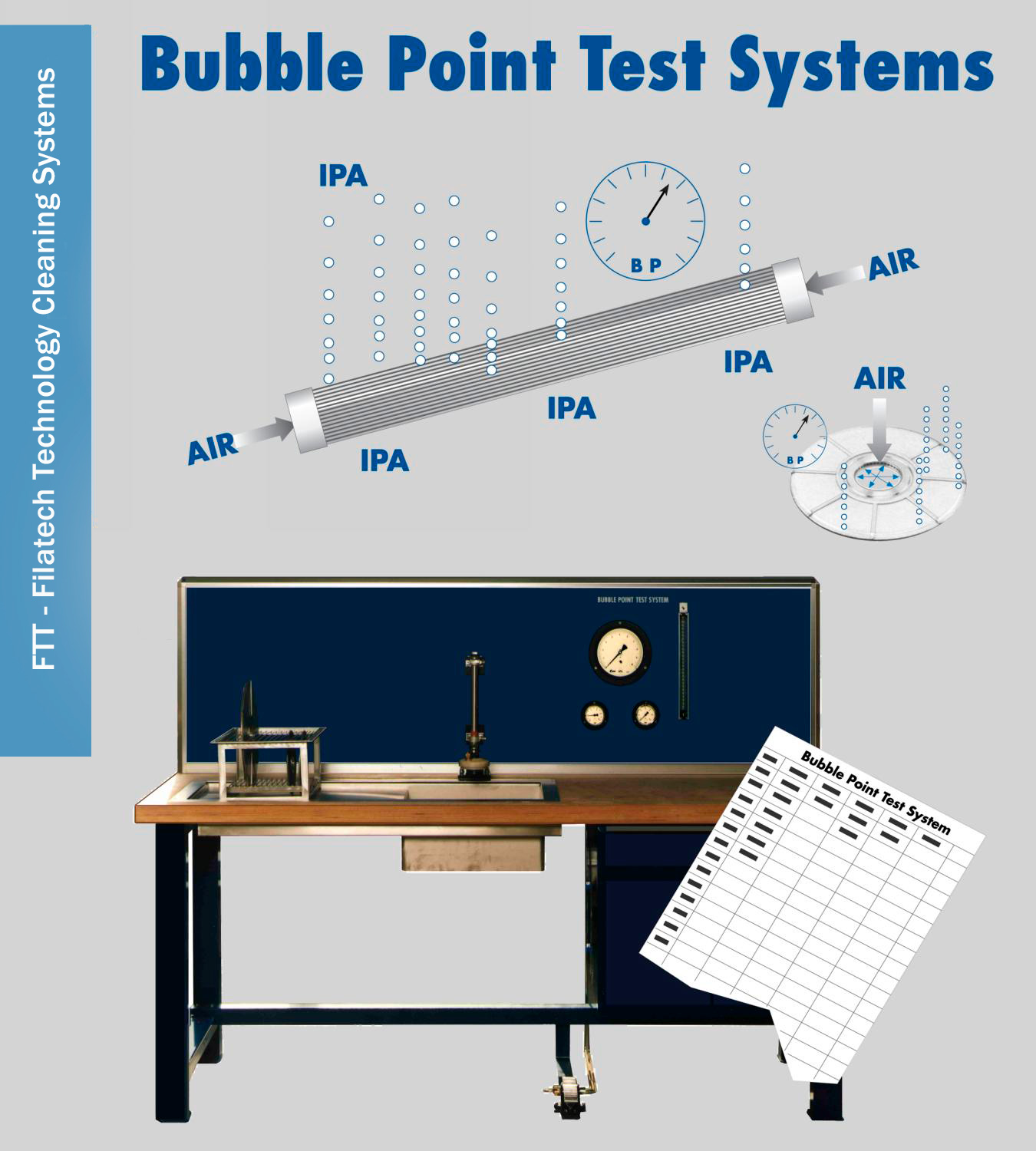

Test systems

Mobile systems and complete test stations for bubble and flow tests for different types of filter elements are available as standard versions. The devices and components are designed for easy handling, accurate measurement and documentation of measured values. Stainless-steel or plastic tubs are integrated for testing the filter elements.

Efficient, integrated test-fluid vapour exhaust systems are optionally available for safe operation of the test stations. A pneumatically operated handling system for filter discs facilitates work during testing. Systems for various filter elements and dimensions are available, including combined systems for cartridges and filter discs.

Other cleaning equipment

Various types of accessories are required for cleaning facilities and workshops. Typical standard accessories include high-pressure cleaners, precision scales, storage tanks for cleaning agents including chemical ones, pumps and much more. Tailored accessories for ultrasonic cleaning systems, disc filters and nozzle cleaning, hydraulic presses for disc-filter modules, rotary and handling devices for filter units, and special tools for filter assembly and disassembly are also available.

Computer databases for saving and retaining filter-test data, including assessments of cleaning history and predictions of lifetime filter-cleaning cycles are available too.

We also offer engineering and consulting services for planning and design of cleaning systems. Included here are workshops as well as implementation of processes for cleaning filters, spin packs and other machine parts.

FTT personnel are available for training staff at FilaTech or at the customer's premises. On the customer's request, we supply consumables such as seals for filters, spin-pack assembly or installation, spin-pack filters and further accessories.